Cut Food Waste, Cut Costs: How Sodexo Fights Inflation

Saving on food costs has never felt so urgent.

Over the past year, foodservice operators saw prices skyrocket. At times, the cost of turkey was up almost 40%, chicken was up 15% and eggs more than doubled in cost, in comparison to the previous year’s prices. Vegetables and fresh fruit were also significantly more expensive.

Foodservice businesses can waste a startling amount of product. A recent report found a half-pound of food is wasted for every restaurant meal, from kitchen waste to customer leftovers. Since Americans eat out about six meals (on average) every week, this means hundreds of millions of pounds of wasted food — worse still, it’s hundreds of millions of dollars wasted by the companies feeding them.

Foodservice businesses can waste a startling amount of product. A recent report found a half-pound of food is wasted for every restaurant meal, from kitchen waste to customer leftovers. Since Americans eat out about six meals (on average) every week, this means hundreds of millions of pounds of wasted food — worse still, it’s hundreds of millions of dollars wasted by the companies feeding them.

Savvy food managers understand controlling costs means tackling waste.

Overproduction, expiration, trim waste, handling, poor cooking and inventory spoilage are the biggest food waste culprits. But by stringently monitoring these issues, savings are not only possible, they’re expected.

At Parkview Regional Medical Center in Fort Wayne, Indiana, monitoring what is headed for the trash bin has allowed kitchen staff to save more than $110,000.

"When we initially started this, one of the biggest eye openers was the visual representation of the waste," Chef Chad Kyle says. Parkview, a 600-bed hospital and medical campus with about 180 employees, has seen the payoff.

"When we initially started this, one of the biggest eye openers was the visual representation of the waste," Chef Chad Kyle says. Parkview, a 600-bed hospital and medical campus with about 180 employees, has seen the payoff.

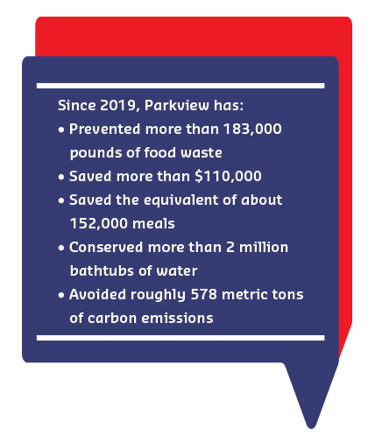

Since 2019, monitoring food waste has allowed Parkview to:

- Prevent roughly 183,000 pounds of food waste, valued at more than $110,000

- Save the equivalent of about 152,000 meals

- Conserve more than 2 million bathtubs of water

- Avoid roughly 578 metric tons of carbon emissions

Previously, dishwashers just tossed food in the trash; cooks might not even know what was wasted, Kyle says. The reports are so impactful. This puts it in our face so we’re aware.

One example, given the inflated cost of chicken: In 2020, Parkview realized it was wasting too much boneless chicken. By challenging the team, chicken waste was reduced by 44% in four weeks, saving 97 pounds of meat.

How Waste Is Watched — and Money Saved

About 2,025 Sodexo sites in 30 countries use a program called WasteWatch powered by Leanpath. It’s a powerful way to partner with our clients by creating a food recovery hierarchy and save them money, too.

The WasteWatch powered by Leanpath system is simple: a scale and visual display. Kitchen staff weigh food waste and enter product information and a disposal reason.

The WasteWatch powered by Leanpath system is simple: a scale and visual display. Kitchen staff weigh food waste and enter product information and a disposal reason.

Over time, the system can identify trends — most wasteful days, mealtimes and dishes. Critically, it also estimates savings in dollars, equivalent meals, water usage and carbon emissions. It then sets waste reduction goals that reset when achieved to drive more savings.

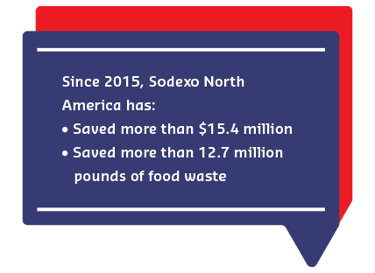

Sodexo North America has already prevented more than 12.7 million pounds of food waste, valued at more than $15.4 million, since we systematically began collecting data in 2015. As more client sites sign on, we’ll save even more. There’s never been a better time.

Want to save this info for your own food waste journey?

Download our Food Waste Insights